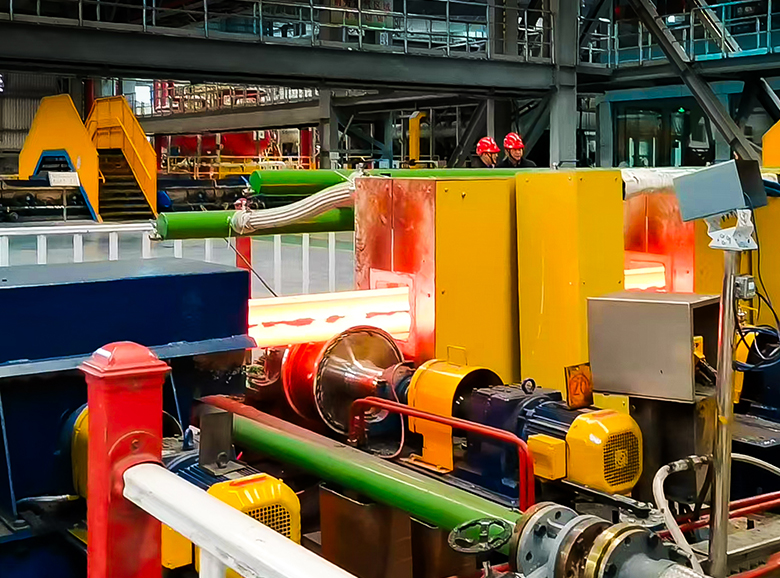

Billet heating /reheating furnace is used in steel rolling mills to heat steel billets to 1100–1250°C, making them soft enough for rolling. It ensures: correct rolling temperature, uniform heat distribution, Stable rolling quality, higher production efficiency, there are two main types: Gas/Oil-Fired Billet Reheating Furnace, Induction Billet Heating Furnace. Each type serves different production needs.

The Gas/Heavy Oil Billet Reheating Furnace is built for high-capacity, continuous steel production, featuring a multi-zone design for uniform heating, PLC-based automation for real-time temperature control, and automatic fuel and flame management for safety. Its high-grade refractory construction ensures resistance to thermal shock, corrosion, and wear, providing long-lasting reliability and efficiency.

Customized design according to the actual requirement of customers.

1:Multi-zone burners (Gas/Oil) or internal electromagnetic heating (Induction) ensure rapid and uniform billet heating, reducing energy consumption by up to 25%. Heat billets to 1100–1250°C in minutes, supporting both continuous large-scale production and flexible batch operations. 2.Uniform Temperature Distribution:Optimized design guarantees consistent temperature across the billet, reducing defects and improving rolling quality. 3.Precise Temperature Control:Real-time sensors and PLC automation maintain temperature within ±3–5°C, ensuring high-quality steel with predictable properties.

Gas/Heavy Oil Furnace: Reliable, high-capacity furnace with uniform heating, durable construction, and precise automated control. Induction Furnace: Fast, energy-efficient, precise, and eco-friendly furnace with uniform internal heating and flexible, compact design.

The Gas/Heavy Oil Billet Reheating Furnace heats billets externally using high-temperature flame and hot gases, transferring heat through radiation, convection, and conduction across multiple temperature zones, with PLC-controlled burners ensuring uniform temperature. The Induction Billet Heating Furnace heats billets internally via electromagnetic induction, generating heat through eddy currents, with infrared sensors and PLC control maintaining precise, uniform temperature without combustion, making it fast, energy-efficient, and environmentally friendly.

| Model |

Furnace Type |

Capacity (T/H) |

Capacity (T/H) |

Heating Temperature |

Fuel Type |

Furnace Length (m) |

Power Consumption (kWh/T) |

Fuel Consumption (Nm³/T) |

| GF-10 | Walking Beam | 10 T/H | 100–150 mm | 1100–1250°C | Natural Gas / LPG | 24–28 m | 30–50 | 60–80 |

| GF-20 | Walking Beam | 20 T/H | 120–160 mm | 1100–1250°C | Natural Gas / LPG | 32–36 m | 30–50 | 55–75 |

| GF-30 | Pusher Type | 30 T/H | 120–200 mm | 1100–1250°C | NG / Coal Gas | 40–45 m | 30–50 | 50–70 |

| GF-50 | Walking Beam | 50 T/H | 150–200 mm | 1100–1250°C | NG / Oil | 55–60 m | 30–50 | 45–65 |

| GF-80 | Walking Beam | 80 T/H | 150–250 mm | 1100–1250°C | NG / Oil | 65–70 m | 30–50 | 45–65 |

| Model |

Output Capacity (T/H) |

Billet Size (mm) |

Heating Temperature |

Power Supply |

Installed Power (kW) |

Heating Efficiency |

Power Consumption (kWh/T) |

Line Frequency |

| IF-1 | 1 T/H | 60–90 mm | 1100–1150°C | MF Power | 600–800 kW | 90–95% | 420–480 | 500–1000 Hz |

| IF-3 | 3 T/H | 80–120 mm | 1100–1150°C | MF Power | 1000–1500 kW | 90–95% | 400–460 | 500–1000 Hz |

| IF-5 | 5 T/H | 100–140 mm | 1100–1150°C | MF Power | 1500–2200 kW | 90–95% | 380–450 | 500–1000 Hz |

| IF-8 | 8 T/H | 120–160 mm | 1100–1150°C | MF Power | 2500–3500 kW | 90–95% | 360–430 | 500–1000 Hz |

| IF-10 | 10 T/H | 130–160 mm | 1100–1150°C | MF Power | 3000–4200 kW | 90–95% | 350–420 | 500–1000 Hz |

*The output will vary according to different materials, feed particle size and other factors

Save Time! Get A Detailed Quotation Quickly.